Toyota Motor Corporation is working to create new value! Will car scrap be reborn as traditional crafts? [Miyagi Prefecture]

table of contents

Toyota Motor Corporation is one of Japan's leading companies

Many Miyagi residents are aware that Toyota Motor Corporation has a huge factory in Ohira Village from which "Made in Miyagi" cars are shipped all over Japan. But did you know that Toyota has also teamed up with Miyagi Prefecture to launch an interesting initiative to transform car scrap into traditional local crafts?

A new initiative called "geological design"

Toyota's in-house structural design studio is working on "making cars with no wasted parts."

Even as we try to reduce the use of resources such as steel and create structures that are easier to recycle, there are still materials that cannot be recycled in the raw materials and components used to make cars

We are creating a system and network of partners to upcycle these materials, adding value to them and transforming them into new products and creations. We have named this entire activity "Geological Design."

Iron from scrapped automobiles turned into knives

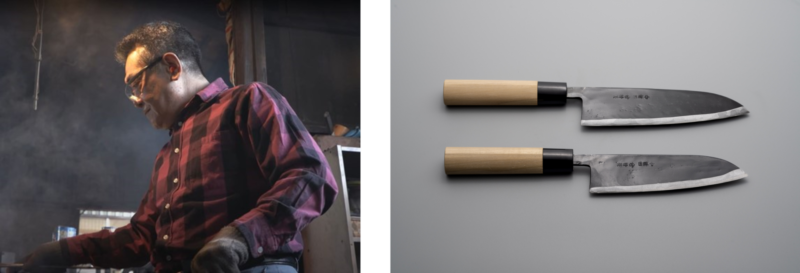

Ishikawa Cutlery Factory in Kami-machi, Kami-gun, Miyagi Prefecture, produces the "Kurouchi Santoku Knife" using scrap iron from automobiles

Nakaniida forged cutlery, which originated in Kami Town, Kami District, Miyagi Prefecture (formerly Nakaniida Town), is a traditional craft that is said to have originated when a cutlery blacksmith from the Sendai domain made sickles in Nakaniida during the Kanbun era (1661-1673) of the Edo period. Ishikawa Michio, the fourth generation owner of Ishikawa Cutlery Manufacturing, which was in charge of the production this time, is said to be the last blacksmith in Kami Town

Ishikawa Cutlery Manufacturing's products are extremely popular overseas, and are traded at very high prices through our five overseas distributors

The Nakashinta Cutlery Upcycled Automobile Scrap Knife produced this time is made from a completely different material than the steel normally used to make knives, so the temperature and the amount of hammering force needed to be changed during the forging process. This was the result of repeated prototyping over a period of about a month and a half

Ishikawa Cutlery Manufacturing Co., Ltd. <Information>

- Name: Ishikawa Cutlery Factory

- Address: 20 Minamimachi, Kami-machi, Kami-gun, Miyagi Prefecture, 981-4241

- Official URL: https://ruraljapantv.official.ec/

Google Maps

Glass from scrap automobiles is turned into glass products such as glasses

Kaiba Glass Studio, located in Akiu-cho, Taihaku Ward, Sendai City, was founded by Koji Murayama in 1996. The studio is involved in a wide range of creative activities, from simple vessels to research into glass materials for objects and lighting, as well as the planning, design, and production of various other sculptures

Here, glass products such as glasses are produced using discarded automobile glass (side glass)

Unlike traditional production methods that involve turning natural materials such as sand and rocks into glass, it can be said that creating works using glass, an industrial material made to uniform quality standards, is an entirely different process

The "upcycled glass products made from scrap automobile materials" that were created this time were apparently the result of about three months of trial and error

Kaiba Glass Studio <Information>

- Name: Kaiba Glass Studio

- Address: 23-1 Nagabukuro-Tateyamahara, Akiu-cho, Taihaku-ku, Sendai City, Miyagi Prefecture, 982-0243

- Official URL: https://kaiba.org/

Google Maps

summary

A new initiative to transform industrial products into traditional crafts

According to a comment by Koichi Daigaku, theme producer at Toyota Motor Corporation's Structural Design Studio, the company is also considering realizing local production and consumption of automobile scrap, using automobile scrap generated by Toyota Motor East Japan, Inc., which has a production base in Miyagi Prefecture

The two products mentioned above are also being considered for general release in the future, so if you're interested, keep an eye out for updates!

![Onikobe's Jigokudani Promenade! The steam and geysers are a sight straight out of hell! [Miyagi Prefecture] 5148713_m](https://jp.neft.asia/wp-content/uploads/2023/08/5148713_m-150x150.jpg)

![The Zaimokuiwa Rocks of Obara in Shiraishi are a natural phenomenon, a spectacular spot for viewing columnar joints! [Miyagi Prefecture] FE8E1C5D-891F-4A2B-B0BB-BB4536BF6858_1_105_c](https://jp.neft.asia/wp-content/uploads/2023/07/FE8E1C5D-891F-4A2B-B0BB-BB4536BF6858_1_105_c-150x150.jpeg)

![[Miyagi Prefecture] Learn the Miyagi dialect! "Dakara" (so), "Ikinari" (suddenly), "Good morning socks"? Good morning socks](https://jp.neft.asia/wp-content/uploads/2023/09/fashion_kutsushita_ana-150x150.jpg)

![[Tohoku] Where should you go during Golden Week 2023? How about visiting zoos and aquariums in Tohoku? 26245129_m](https://jp.neft.asia/wp-content/uploads/2023/04/26245129_m-150x150.jpg)